Sanding your turnings can be a chore or an element that sets your turning apart from the ordinary. As I have focused on achieving a smoother finish my turnings look and feel that much better. Sanding is a process that most turnings should go through.

Sand Paper and Sanding in General

Sand paper or glass paper comes in different grits. The number of particles per square inch is the grit number of the sand paper. So 120 grit sandpaper has 120 particles per square inch. Therefore the higher the number the finer the size the particle is that does the sanding.

Even though it feels smoother used sandpaper does not become equivalent to a higher grit. One turner has said: “Sand your work as if someone else paid for the sand paper.”

The sanding process for turning is similar to regular woodworking. You start with a sanding grit that removes tool marks and sands the wood to its finished shape. For major changes in shape you would start with a low grit of 50 or 80. Depending on how your tools have finished the turning you can start with higher grits.

A general rule of thumb for increasing the grit of your sand paper is to limit your jump to 1.5x the current paper. So if you are using 120 grit sandpaper you would move to 180 grit. It is a rough guideline to follow. Standard grits are as follows: 50, 80, 120, 150, 180, 220, 320, 400, 600, and 800.

The reason that you don’t jump too far to reach the next grit of sandpaper is that you want each grade of sandpaper to remove the marks of the previous grade. If you jump too far your particle size will be too small to remove the marks from the previous sandpaper.

Each time you use a piece of sandpaper you leave grit and sawdust on your turning. After each grit remember to wipe the turning down with a soft cloth or paper towel. This removes any grit that has fallen off of your sandpaper so that you don’t accidentally make scratch marks on your turning when you use the next grade of sandpaper. That can be very frustrating.

Sanding Safety

Sanding on the lathe produces sawdust. This dust is hazardous to your lungs and you should always wear a dust mask or respirator. Some woods are toxic and may need to be wet sanded. That is a topic for a future post.

Sanding Organization and Efficiency

I organize my sand paper into stacks that move progressively through each grit size. I find that 1/4 sheet works well. They are easy to hold and shape to fit my turnings. I cut the sandpaper into four quarters. Fold the paper together so that the grit is on the outside then use a sharp knife to cut the paper not the particles. When you cut your paper if the printed grit size is not visible quickly write it in on the back of the paper. It is not easy to judge what size grit is on an unlabelled piece of sand paper.

As I go through the grits I rebuild the stack. Once I am done sanding I flip the stack over and I’m ready to go on the next section. This keeps the paper in order and I don’t have to always check the grit size that I’ve grabbed. I’ve used clothes pegs to keep the papers altogether between sessions.

These little tips increase the efficiency of your sanding so that you can quickly move on to your next project.

Sanding your turnings

For this post I have turned a rolling pin. My last cuts on the pin were made very lightly with a skew chisel. This gives me a very good finish and I’m ready to start sanding with 320 grit sand paper.

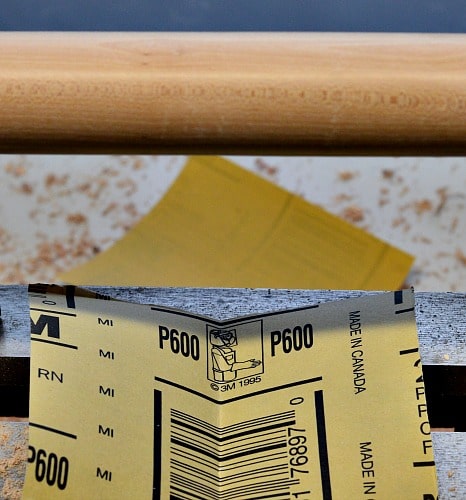

These are the four grits of sandpaper that I will use. 320, 400, 600, 800.

Here is the rolling pin sanded with 320 grit sandpaper. If you compare the previous image with this one you can see the difference the first sanding makes.

At this point I decided to add burn lines to the rolling pin. Using 400 grit sandpaper is the next stage.

Two more grits are left. Use the 600 grit sandpaper.

Finally the last grit is 800 grit sandpaper. There is no magic to using 800 grit sandpaper and you can actually keep sanding to even higher grits. This is what I am used to and I like the feel that this grit gives my turnings. Depending on what the turning is to be used for you can sand to a different grit size.

At this point you add your finish or wax to your turning project. As this is a rolling pin I used a food safe wood polish as the finish.

To show you the impact that sanding makes here is a collage of the rolling pin as I sanded through each grit. (I accidentally missed 600 grit.)

I would love to let you hold the rolling pin. Your fingers are very sensitive and will let you know if there are any imperfections. This is important with the first grit you select. If you find that the turning is still rough to the touch, or the transitions on the curves feel abrupt rather than smooth, then try a lower grit sand paper. It is at the start that you set the foundation for your turning.

Depending on the item you are turning you will need to go through the sanding process multiple times on the project. With a box or a bowl you will be able to use the spinning lathe to help you sand at specific stages in the turning process. Remember to go through all the grits in order each time you sand a section of your turning. Turning a coin bank required sanding at different points in the turning process.

Sanding is the boring part of turning. There is always part of a job that is mundane. If I defined what I did by the amount of time it took I would be a wood sander not a wood turner!

You may have to ask local woodworkers where they get their higher grit sandpaper. In my town I buy it from the auto supply store. The hardware stores don’t carry much selection and usually don’t go higher than 320 grit. It may take a bit of effort but the results are well worth it.

To get a good finish on your turning, sand progressively through the grits, and wipe with a soft cloth between each change in grit size. If you have a turning that you particularly proud of please share it with me. I would be glad to see it.

Please sign up for my free newsletter. It comes out weekly with projects and other information that I think you will find useful.

[…] you have shaped the rings then go through the sanding process to your finest grit. Having the rings attached to the blank will speed up the sanding process. […]