I’m going to purchase a mini lathe. During the winter months the shop is way too cold and it would take forever to warm up even standing 6 feet from the wood stove. A mini lathe would let me turn pens, small spindle turnings, bird houses, Christmas ornaments, small bowls, and lidded boxes. The larger stuff would have to wait for the shop to be warmer. So what do you need for a mini lathe?

Physical Placement of the Mini Lathe

While the mini lathe is smaller the turner remains the same. So the mini lathe needs to be at the correct body height as you’d need for a full size lathe. The center should be about 2” above the height of your elbow. So you will need to place the lathe on a work bench that is a suitable height.

The footprint of the lathe fits in a 1’ by 2’ area. You do want lots of room to move around your lathe so more space is better than less. If you cannot turn the headstock then you will need at least 2 ½ feet at the end of the lathe to turn bowls. Moving the headstock to the end of the lathe bed will allow you to turn larger bowls.

You want good lighting both overhead and directional. This will show you the turning in all its detail without shadows.

Characteristics of the Mini Lathe

The weight of the lathe is important as well. The heavier the lathe the less vibration there will be, which will allow you to take cleaner cuts. You should select a lathe made out of cast iron rather than aluminum or steel rods. In addition you can attach your lathe to a bench then weight the bench down with a heavy material. One wood turner uses bags of ready mix concrete. I’ve used pieces of old railway iron.

Normal house current is suitable for powering a mini lathe. Most mini lathes have a ½ hp motor. A ¾ hp motor would be better but would increase the cost significantly. For most turnings the 1/2 hp motor is suitable but if you are pushing the capabilities of the mini then you would need to be more careful. The farther the wood extends from center the greater torque is placed on the machine. This includes taking lighter cuts on larger diameter spindle turnings, and on larger bowls. The blanks should be trimmed close to round so as to reduce the stress on the motor and spindle shaft from an unbalanced piece of wood.

Speed control on mini lathes is normally done through changing belts. This does take a bit of time so ensure that it is easy and straight forward. Variable speed controls are available on higher priced models.

Typical mini lathes have a depth of 5” for turning bowls. You can turn a 10” bowl and spindle lengths up to 15”. You can get an extension for some lathes to allow you a greater length, enabling you to turn table legs, railings etc.

Again remember that the larger the turning, bowl or spindle, the greater the stress on your lathe.

As with all lathes the tool rest needs to be adjustable along the bed as well as height. The easier it is to adjust the tool rest the easier it will be for your turning!

Accessories for the Mini Lathe

The tools that you use with a mini lathe are the same as you’d use on a full size lathe. However, smaller diameter gouges, and slightly smaller skew chisels would facilitate turning smaller projects.

The spindle, this is what turns the wood, will often be a 1” spindle with 8 tpi outer threads. The inner core should be a MT2. These are the common sizes. You’ll want to match the characteristics of your regular lathe so that the accessories you have will fit all of your lathes. Then you won’t need to buy two different sets of accessories.

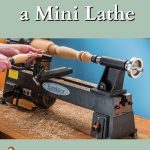

As can be seen in these pictures a simple base can be built to support the mini lathe. You can make it as simple or as complex as you wish. A bottom shelf to add weight to would be an excellent idea.

The chip collection could be with a vacuum system. Or you can use drop sheets, or old shower curtains to control the spread of the shavings.

Since I hope to turn in the house, my wife will be happier if I set up a system to keep everything clean. Happy wife, happy life.

Mini Lathes under Consideration

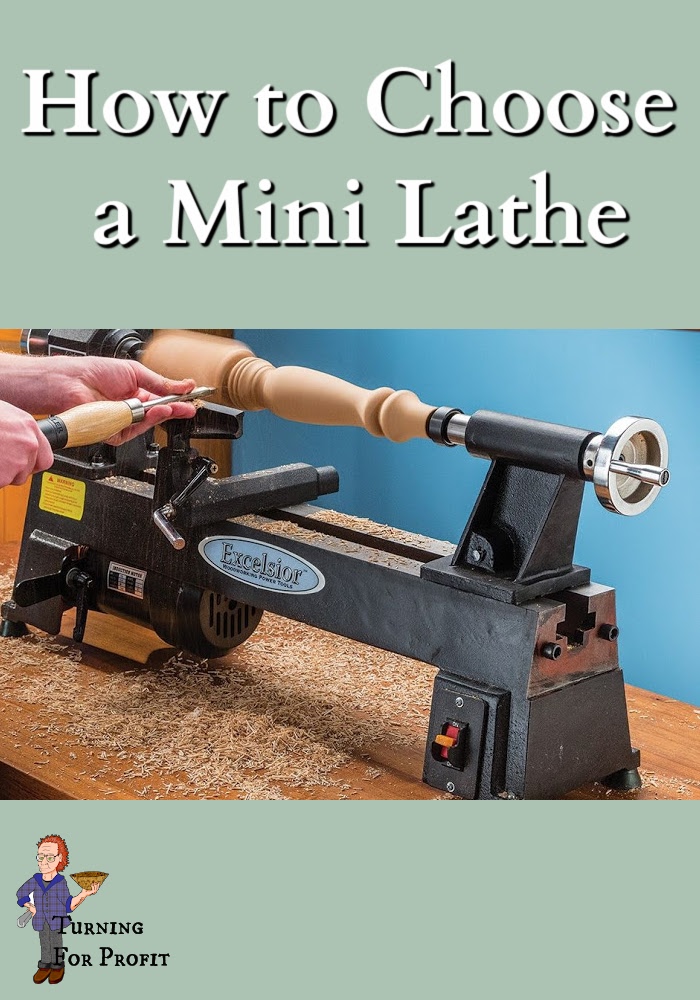

I am thinking of purchasing one of the following: Rikon 70-100, Jet 1015, Turncrafter Commander 10″ variable speed, or Shop Fox W1704, Excelsior MC-1018. Here’s a picture of the Excelsior Lathe:

In a bit of serendipity the Excelsior MC-1018 lathe is on sale this week from August 2 to August 7. Its on sale for $ 100.00 off.

Which one do you think I should get? If you have had experience with a mini lathe, good or bad, leave me a comment below and let me know. Thanks.

Should you get a mini lathe?

The advantage for the mini lathe is that it is reasonably portable. Yes, it still has a good weight but it can be taken to the cottage, to a wood show, or a workshop, or in my case, brought inside the house for winter turning, when my outdoor shop is too cold to be comfortable.

Thanks to Ken Lowder and Joshua Driver who provided the pictures of the mini lathes in this post.

Your turn:

What’s your experience with a mini lathe? Do you have any advice to share?

[…] July I posted on what to look for in a mini-lathe. Well, Rockler had a sale on its Excelsior Mini-Lathe, the features were very similar for all of […]