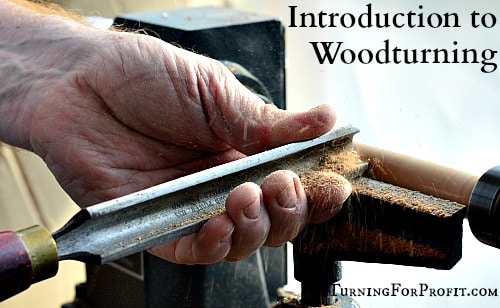

Okay, I’m guilty. My turning lately has been sporadic. Now before you leave the page, hang on, there were reasons and some were even good ones! All kidding aside, whether it has been two years or two weeks your wood lathe needs maintenance. In addition to maintaining your lathe make sure you always turn safely as well.

I’m going to run through a maintenance schedule from daily to quarterly just to make sure everything is running great. What will need to be done will depend on your machine, how often you turn, and what type of turning you do. Turning green wood will create conditions that promote rust on your rails that seasoned turning won’t, so adjust the maintenance to suit you.

Every time you turn on your wood lathe

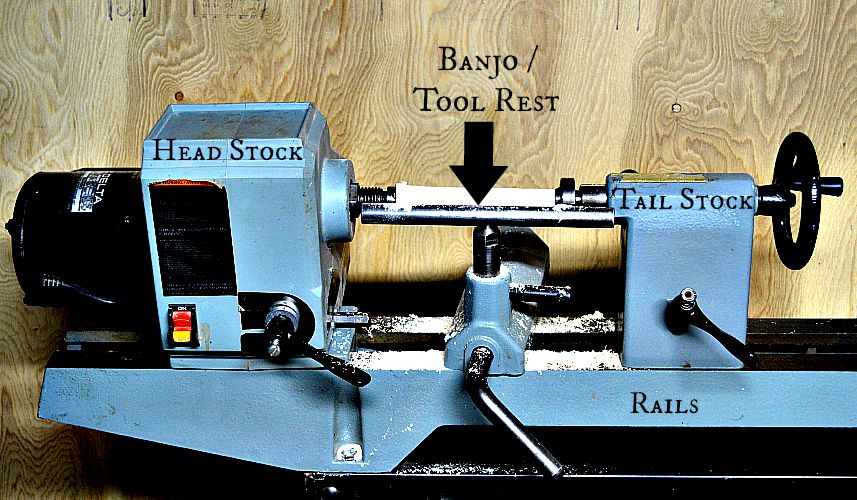

- Eye ball the main parts of the wood lathe, head stock, tool rest, and tail stock. Are they in the right position? Has the tool rest been knocked out of place? Even in a one person shop I’ve bumped the tool rest and moved it into the work I was going to turn.

- Is the wood still secure on the lathe? Check your chuck for bowls and your tail stock for between center work. Loose wood on the lathe is not a good idea.

- Does the work spin clear on the lathe? Always turn your wood by hand to ensure that everything is clear and the wood can spin freely.

- Remove any clutter about the lathe. Check not only where you are turning but around your feet as well. You don’t want to trip as you are making a long cut on a table leg.

These are good routine habits to protect yourself and to keep from damaging your wood lathe.

Daily Routine

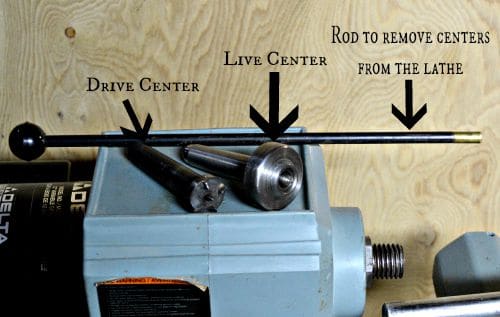

- Each day that you turn you should clean out the two Morse tapers (head stock and tail stock). This will make sure your drive spur and live centre will seat securely and with proper alignment. Any debris in the taper will push the points out of alignment which will affect your turning. This is more critical the smaller and finer your work is, such as a delicate finial. I use an old toothbrush but you can also buy a Morse Taper cleaner.

- Smooth down and wax your tool rest. This keeps the edge smooth rather than bumpy which will improve your long cuts on your turning.

- Wipe down and silicon the ways, or rails, of your wood lathe. While some people wax the rails this could lead to debris build up. A silicon spray reduces the friction of the banjo and the tail stock so that you can easily move them across the lathe.

- Take that old toothbrush and clean the head stock threads. This is what holds your faceplates and chucks secure. Again we want a good snug fit that will maintain alignment with the tail stock so get rid of any sawdust or debris on the threads.

- At the end of the day, brush off your wood lathe and sweep up your shavings. This will maintain a clean and safe place for you to work.

Weekly Routine

- Use a metal file (Mill or bastard) to smooth down the top of your tool rest. Your turning tools are usually harder steel than your tool rest so over time the tools can dent and nick your tool rest. Do long, even, and smooth strokes. A little bit on a weekly basis will keep the surface smooth and easy to work with.

2. Remove the quill (the inside part of your tail stock) and smooth out any rough spots with a file or sand paper. You want to keep your locking screw on the inside of the slot on your quill. This will keep your quill stationary and secure. It is easy (I know!) to have the quill turn so that the locking screw is now on the quill barrel instead of in the slot. This does not hold the work as securely and can mar the barrel of the quill hence the maintenance check. If you have to turn the locking lever really tight to hold steady it is probably out of place. Lubricate the quill with some silicon as well. Use the toothbrush on the interior quill housing then put everything back.

3. With a drive spur in the head stock and a live center in the tail stock, bring the tail stock up to the head stock and check the alignment. You need to check both horizontally and vertically. This is where I found out a little debris in the tail stock taper affects your positions. If your head stock rotates you will need a double ended Morse taper to completely center your lathe. A shim under your tail stock or tightening the hex nuts on your locking mechanism will give you a snug lock and good alignment.

4. Use compressed air to blow out your electric motor. This will reduce overheating and extend the life of your motor.

Quarterly Maintenance

- Banjo/Tailstock check. Take both items off of the wood lathe and flip them over. Blow / wipe off any debris or sawdust. Check the areas that travel along the rails and make sure they are smooth and clean. If needed file them to remove nicks or rough spots. Replace on the lathe.

- Check the Nylock nut on your headstock, banjo and tail stock. These nuts are crucial to holding these parts in place. If they are lose tighten about a ¼ turn and check for fit. If they become stripped from over tightening you can get replacements at your local hardware store.

- Drive belts. Unplug your wood lathe first! This applies to lathes where you move the belt to change the speed and to variable speed lathes. If you have to move the belts to change speed then open up the access doors and specifically examine the belts. Is there any wear or cracks? On a variable speed lathe you will have to remove the cover over the drive mechanism and check the belt that way.

- Electrical review. Use compressed air to blow out switches, motors, and capacitors. Check all visible wires for cracking, melting, or other signs of wear. How is the plug on your wood lathe? Look along the electrical cord as well. It is too easy for another tool or stand to be placed on the electrical cord and damage it. If it is damaged replace it or have it fixed by an electrician.

A wood lathe that is well maintained and tuned will be a joy to use and safer as well. Don’t forget to put everything back together. For more tips like this please sign up for my email newsletter.

Here are a few projects you might like to turn now that your lathe is up and ready to go.

For the Kitchen: A Scottish Spurtle

For the gardener: A Seed Starting Pot form

For Christmas: Christmas Trees and Wooden Icicles

For the puzzle lover: The Tower of Hanoi

Need more ideas? Check out the project index here.

Safety is more than just doing the right things to keep you safe. It is an attitude and awareness that has to be with you every time you are in your shop, working on your lathe, or using other tools. You are more important than any project or deadline. Keeping your tools in good working order is an important safety protocol.

How to Choose a Mini Lathe

How to Choose a Mini Lathe

[…] addition to turning safely, basic lathe maintenance will allow you to enjoy many hours turning at your […]