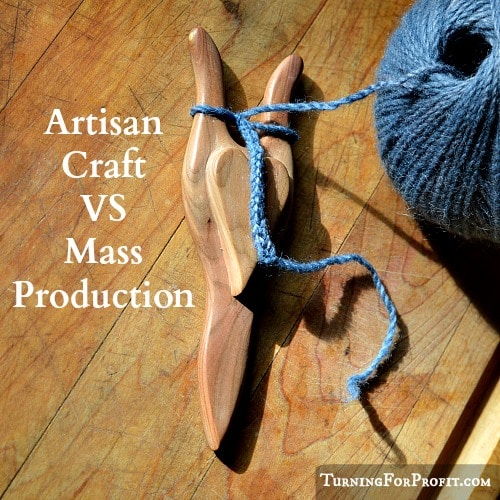

Balancing the need for repeat production with artisan aesthetics

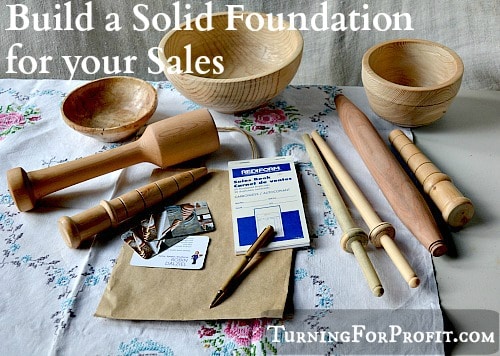

Tupperware is famous for its storage utility, and its ubiquitous presence in every home. Tupperware is cheap, easy to make, convenient to use, toxic, and stack-able. A wooden bowl reflects character and charm. It is a joy to use and to look at. There is the warmth of its colour and the texture of its wood. We used to have only wooden bowls. They were used to make bread, mix dough, and hold fruit or salads. Now wooden bowls are rare. Plastic bowls are the norm. But which would you rather use?

Plastic bowls are the result of mass manufacturing processes, assembly lines of automated equipment producing millions of identical products. Wooden bowls require craftsmanship, care in production and individual attention to detail. It takes time to produce a wooden bowl on or off of the lathe. If a storage container is all you need it is hard to beat plastic. Wooden bowls have an aesthetic that far outshines the utility of plastic. However, the craftsman can learn from the efficiencies of mass production yet maintain the artistic nature of their work. The challenge to the artisan is to utilize these efficiencies to increase the time available for the artistic aspects of production.

So in the development of products, the artisan needs efficiency and uniqueness. These two concepts seem to be opposed to each other. Efficient production means that our time is not wasted and our return improves. How do we manage this without becoming robots? Uniqueness gives the product the qualities that make it attractive and artistic. Can efficiently produced products still maintain their artistic merit? Let’s examine a single product and see how these issues are identified and resolved.

I make lucets. These are used to produce a tight cord that can be used for straps or handles or tying things together. They are a nice shape and fit comfortably in your hand. I made 20 or so last year.

Production of a lucet

You need a thin piece of wood roughly 3/8″ thick. Trace the shape of the lucet on the board then cut it out on a band saw or use a scroll saw. A drilled hole can be placed at the bottom of the fork if turning the corner is awkward with the saw. A small hole can also be drilled in the middle of the handle for the cord to go through if you wish. This is your rough blank for a lucet. Using a carving knife I whittle the shape round and decide if a carving is going on the handle. I use a wooden handled knife and small carving gouges to make the designs. Next is the sanding. Start with 80 grit paper cut into quarter sheets and folded then in half. This is the longest part of the process. The 80 grit paper allows you to shape and smooth all of your knife marks off of the lucet. You may need two sheets to complete your first lucet. From here I process rapidly through the remaining grits, 120, 200, 320, 400, 600, and 800. Why so fine? The lucet is used with yarn and the fibres will catch if the tool is not impeccably sanded. I finish off with either carnuba wax or a wipe on paste wax and a good polish with a soft cloth.

Process Analysis: Increasing efficiency

Okay. The process is not hard. Where can the efficiencies be increased?

The production of the blanks is an assembly line. Cutting the wood to the right thickness on a table saw or band saw goes faster if you use fences and jigs for a repeatable set up. This is safer. It makes sense to do ten or so boards at a time. I usually do boards that can produce three or more lucets then I have more wood to hold onto as I am cutting. Marking the outline of the lucets goes quickly using a cardboard template.

I usually cut out one lucet at a time on the band saw, but you could tape multiple boards together to cut out more than one. Use duct tape or masking tape to keep the pieces together. Safety first. Do one at a time if you are not comfortable with more.

Artisan craft: Making it yours

The carving of the lucet is the unique part of the production. Not a whole lot you can do here to speed up the process except for the quickness that comes with practice. This is where you adjust the product for the characteristics of the wood, emphasizing the grain or adding a carving for effect.

For sanding prepare the sheets of sandpaper first and place them in stacks of ascending order. Remember to include double the number of 80 grit papers. I usually sand one lucet from start to finish!

Since I produce lucets in the evening as a time of quiet and rest, I am satisfied with one lucet at a time. There might be some reduction in time with carving 5 lucets then sanding all 5 with 80 grit and so on.

This production system allows some efficiency and produces products that are individual in nature. Each lucet will be different. The customer will select based on the feel of the tool in her hand and the attractiveness of the wood and carving. Some will be wider or narrower, thicker or thinner, the prongs will have slightly different shapes etc. So the end product has individual characteristics that will be attractive to the customer.

Let’s take this product to mass production that you would see in a manufacturing plant. This is how their process would work. All boards would be provided at the same thickness. Cutting would be done on large router tables with the wood clamped in place and computers directing the cutting. The router bit would produce a quarter round cut top and bottom so the entire lucet would have the same profile. There would probably not be carving on the handle but other designs could be stamped or burned on in a repeatable fashion. Sanding and finishing would be automated. The finished products would be identical. There would be no reason to select one lucet over another. The wood grain would differ slightly between them but that is all. These lucets would sell for a much lower price than mine.

This shows you the difference between mass production and artisan work. As an artisan I want to create a product that reflects my input and skills. Some of the pre-production work and post production work can be made more efficient by streamlining the activities. However the carving of the lucet is what makes that product mine. Greater efficiency at other points allows more time for the carving.

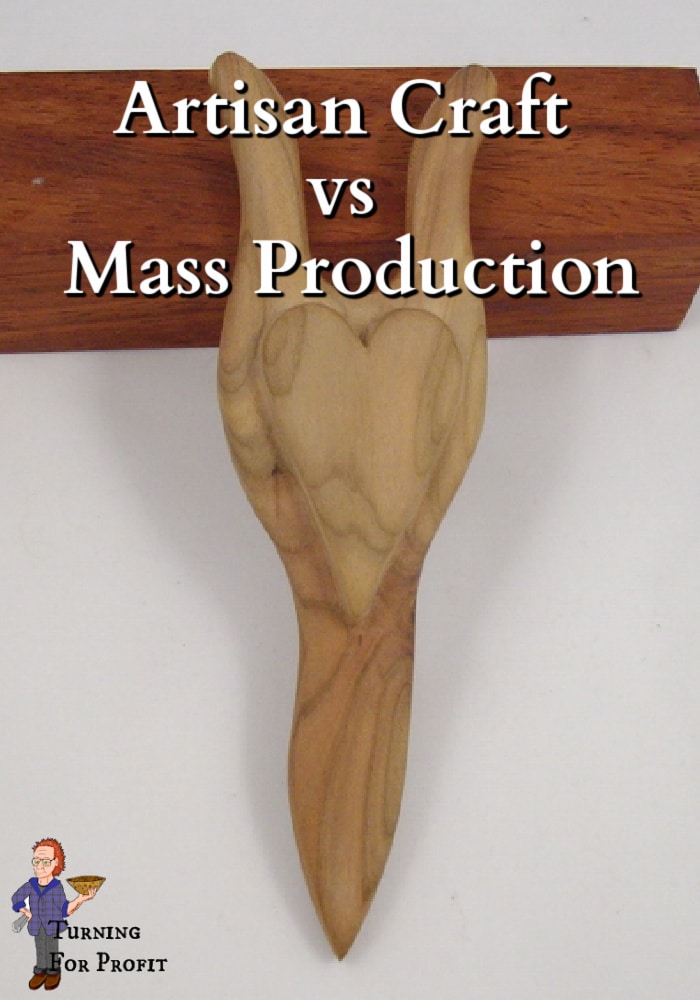

I also made a lucet last year out of black birch. It was started the same as the other lucets but was much harder to carve. The carving of the lucet, and the heart on the handle, took much longer than I expected. This lucet would have cost 3x as much as the regular lucets made out of Aspen or Pine. I figure that most customers would not understand the difference in the wood and not see the need for such a jump in price. I enjoyed making the lucet and I gave it to my daughter. This was a labour of love and the time no longer mattered. However, to stay in business, as an artisan, I need to keep my work as efficient as possible while maintaining my artistic input.

Back to you:

What have you done to streamline your production process? Have you ever faced the challenge of time and the price of your product?