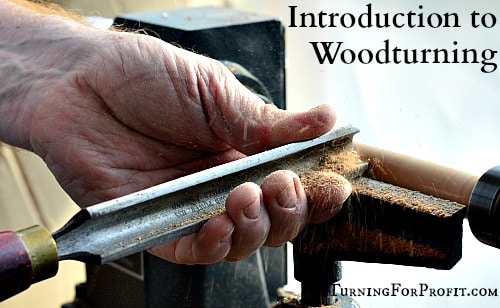

How I Started Turning

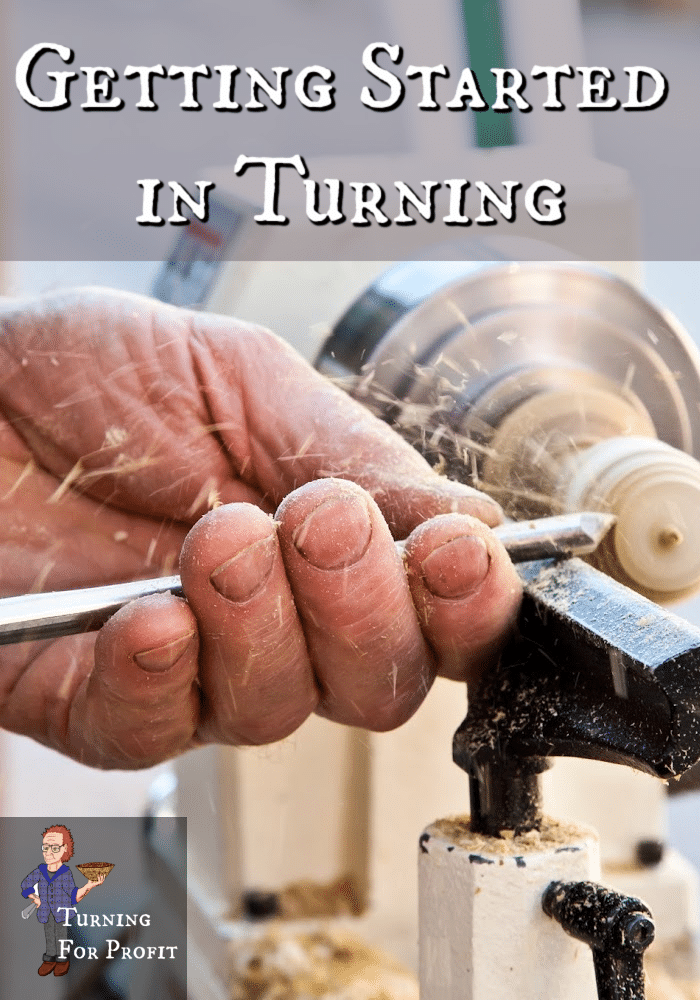

Too many years ago, in my first year at university, I was allowed to turn on a lathe. I was given a lovely wood blank and I turned a chunky but respectable candlestick in one night. The host let me loose on his lathe and didn’t even stick around to provide tips on how to use the tools. I learned as I went. This whetted my appetite so much that years latter I thought I would like to turn.

My initial attempts at turning wood were very frugal in nature. The internet was in its infancy. The books from the public library were already 30 years old and with few pictures. There were no wood working guilds in my town. First I attempted to build a pole lathe in our basement. The idea came from an old turning book. My basement ceiling was only 6.5’ in height. I am 6′ 2″. I found a spot to build a frame jutting out from the wall that would hold the head stock and tail stock for spindle turning. The power for the lathe would come from a pole attached to the ceiling and a pedal on the floor. Although I had done some general woodworking before, my turning experience was limited to the single occasion. Therefore I had no clue as to the forces needed to cut wood on a lathe. Since I wasn’t sure if I would like turning I used my wood chisels rather than buying specialized turning tools. Don’t do that. Just saying.

My first attempts resulted in broken string and cords until I found something strong enough to be the rope connecting the pedal, the piece of work, and the pole over my head. I found that I didn’t have much room to lift my leg on the pedal, so that the pole wouldn’t hit my head on the way down. My wood chisels caught on the turnings, due to their bevel and my inexperience. A couple of good catches on the wood easily dislodged both the head stock and the tail stock. So much for attempt #1.

Over the next couple of months my desire to try turning grew, in spite of the setbacks with the pole lathe. I spotted a kit to turn your drill press into a vertical lathe. You clamp the assembly to your drill press. Center the end of the wood in your drill chuck, while the opposite end is on the pivot attached to your drill press table. There is a long bar that you can adjust with a hex wrench to be the correct distance from the turning. Getting everything set up was quite tricky. On the vertical lathe I actually managed to round a piece of wood. I was still using my wood chisels but maybe a bit more cautiously than I did on the pole lathe. So I did do some turning but I can’t remember anything that I made. The process was frustrating for the set up and tolerable for the turning. I still have the bar and base but not the inclination to use that it. A regular lathe is much too easy in comparison. Attempt #2 was more successful but I knew it was going to get better.

I had enough enjoyment to encourage me to buy a real lathe. With a bit of research I purchased a Delta full sized lathe and a set of turning tools to use with it. After going through some 2×4 turning blanks for practice I did start and finish some regular spindle turned items. It was a haphazard way to develop a hobby.

What I Learned

In hind sight a few things would have helped me.

- Finding someone who was already turning wood, with a few years experience under their belt, would have taken years off my learning curve. Having a mentor would have helped me understand how to use the tools, prepare the wood, and which tools to use when. Instead I had to learn by trial and error. I turned a lot of firewood over the years.

- The printed resources that are available today with step by step visual tutorials would have helped too. They are great in showing what the printed word is trying to say. My first turning books were full of words and no pictures. I am an active guy. And face it, art is a hard thing to learn with only words to guide you.

- Joining a guild or woodworking club that would allow a person to try their hand at turning before committing the funds, would have helped. With the internet, online videos, wood turning tutorial DVDs, and abundant pictorials for wood turning, it still helps to have a place to try it out before you start. Try it before you buy it.

- Knowing which tools are absolutely essential for successful turning and which tools can be bought later, would have empowered my turning budget. I still have tools that I bought at the beginning that I hardly use.

My Recommendation

The Frugal Woodturner from Fox Chapel Publishing is an excellent resource in guiding beginning turners through the establishment of their hobby. It also has lots of tips and tricks for the more experienced turner as well. Chapter seven gives three different starting set ups based on three different budgets.

The tight budget / Basic Setup recommends a used full sized lathe or a new mini lathe. Woodworking groups or craigslist.com are good places to look for used lathes.

Essential starting tools:

½“ bowl gouge

1” or 1 ¼” dome scraper for bowl turning

½ “ spindle gouge

1” roughing gouge

1” skew

a parting tool

Conover recommends a couple of face plates and Beall spindle taps so you can make your own faceplates that will fit on your lathe’s spindle. For sharpening an inexpensive pocket jig is suggested. Hopefully you will have an assortment of other woodworking tools on hand to size and rough shape your wood. The total cost should be under $ 600 if you can find that used lathe. He also has recommendations for people with more money.

The Frugal Woodturner: Make and Modify All the Tools and Equipment You Need

Starting out in a hobby it is better to start small and expand as you and your experience grows. This, of course, is the advise for people who won’t be inheriting a wood working shop.

Your turn:

If you are a turner how did you start turning? If you are just starting out what is your experience with equipment and tools? Please leave a comment.

Recommended Resources:

Delta Industrial 46-460 12-1/2-Inch Variable-Speed Midi Lathe

Crown 280PM 5 Pieces Pro-PM Powder Metallurgy Woodturning Set

DELTA 46-936 3-Inch Face Plate for Wood Lathes

I’ve always thought that I would love wood turning. I appreciate your advice to find someone that has been doing it for a while so that the learning curve doesn’t take quite as long. This would seriously be a dream of mine to master this skill, so I’ll look for someone who can mentor me!

Hi Moira,

If you are on social media you might be able to make some connections to a more advanced turner. There is a Facebook page for turning for profit and attached to that is a Facebook group “Woodturning Entrepreneurs” follow this link https://www.facebook.com/groups/woodturnershub/ and ask to join. Then see if anyone is in your area. Woodturning is fun so I hope you find someone.

Thanks for posting the video! I’d love to get the news letter and learn more.