The parting tool is one of the first tools that most turners get with their lathe. The obvious purpose is to help you “part” the turning off of the lathe. However the tool is much more useful than just getting the wood off of the lathe. So let’s take a look at two different parting tools then move on to ways you could use your parting tool.

Typical Parting Tools

I started with a 1/8” wide parting tool. That is fairly thin. The metal of the tool is nice and solid and comes to a point. You can flip the tool and still work with it. The other parting tool is only 1/16” wide. Because this is thinner the shape is changed to give the point more support.

Cleaning up the ends of your spindle blank

Sometimes when you put rough wood on the lathe your ends are not square. They can be on an angle or just plain uneven. Using the parting tool to clean up the ends of your spindle helps keep your spindle balanced, your other cuts smooth, and a sharp or unexpected edge away from your fingers.

Parting wood off of the lathe between centers

Turning a fish bonker is a good spindle turning project with a good sized piece of wood. After shaping the bonker, sanding, and then finishing you are ready to part the project off of the lathe. As the drive spur and the live center are holding the wood securely you need to remove the wood at each end. So the goal is to make the nub of wood small enough to be easy to remove when it is off the lathe, but large enough to keep the wood spinning on the lathe as you part off the other end.

Parting wood held in a multi-jawed chuck

A multi-jawed chuck can grip your spindle turning without the tail stock for support. For safety reasons use the tail stock if you can. Once you completed as much of the project with the support of the tail stock then you can remove it. This leaves the tail stock end of your turning unsupported. If this is a small spindle and not too long you can then take a skew chisel and finish off that end of your project.

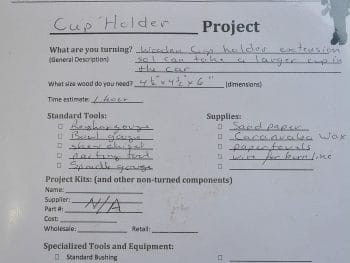

Making tenons with a parting tool

Tenons are very useful in turning. You can make tenons to fit into various sized chucks or you can turn tenons on projects that will fit together for the project. The 1/8” parting tool works best because you are making a wider cut with each use of the tool. For my multi-jawed chuck a 3/8” tenon gives me a good amount of wood to grab in my chuck and I know that three cuts of the parting tool give me that depth. When making a lidded box I turn a tenon on the bottom of the box.

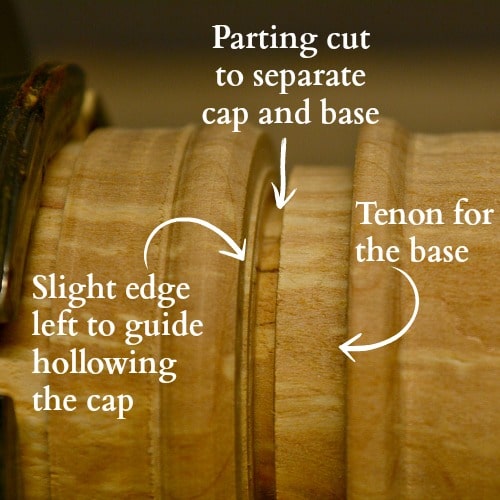

Turning lidded boxes

Turning a lidded box is a great turning project. The trick to this is the parting tool. You turn your blank round between centers on the lathe. On the bottom end you make a tenon with your parting tool. Then turn your blank round and figure out where you want the joint on your box to go. The parting tool is going to be used to separate the lid from the bottom of the box. When actually separating the two pieces don’t make your parting cut flush with the bottom. Move your parting tool away from the bottom just a smidge so you can see a small ridge.

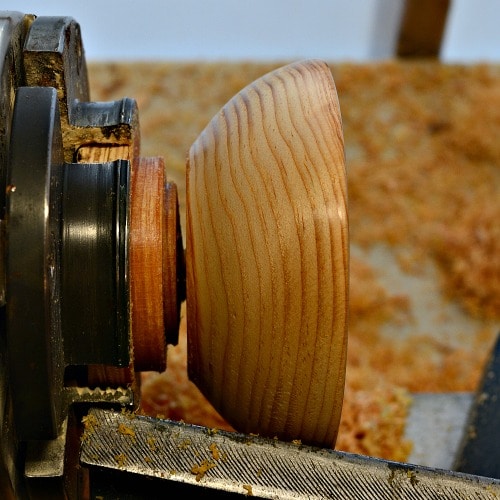

Parting off bowls and lids

When turning a bowl on the lathe and holding it by a tenon in a multi-jawed chuck the parting tool can be used to part the bowl from the lathe. Turn the outside of the bowl to your desired shape. Hollow the interior of the bowl and finish both sides of the bowl. When you are ready to separate the bowl off of the lathe take your parting tool and part it off. To make the bottom of the bowl flat, even with some wood movement, angle your parting tool towards the center of your bowl. Not a lot, you are not turning another bowl. Just a slight angle will give you a concave bottom that will allow your turning to rest steady on a table.

Decorative and functional use of the parting tool

This honey dipper has the slots on the dipper end made by a narrow parting tool. When turning the dipper you can shape the head and then use the parting tool or in the opposite order as well. These slots allow the dipper to hold more honey so in this case they are functional.

Accuracy and placement with the parting tool

The parting tool is a precise width. This allows you to use the parting tool as a measuring device on your lathe. A half inch tenon requires 4 cuts with the 1/8” parting tool. A suggestion that came from the woodturning Entrepreneur Facebook group was to turn the 1/8” parting tool on its side. This gives you a very sharp point. Using the parting tool this way gives you a groove on your turning. This can be a measure of where you want to make your parting slots, or possibly a burn line on your turning. To make the groove move your tool rest away from your turning. Present the tool from the bottom side of your turning and slowly raise the tip to the spot you want to make your groove by lowering the handle. Don’t be too aggressive here you just want a mark on your turning. This is basically similar to using a scraper on your bowls. You want the cut / scrape to be made below center on the turning.

Turning For Profit

A parting tool is one of the easier turning tools to use. As you saw above you can use it in a variety of ways. If you are just starting out turning wood have a look at my Woodturning Blueprint book. It introduces the tools you need to turn and suggests seven progressive projects to help you build your turning skills. There are also business information included for each project. Once the turning bug has bit you will have more products than you know what to do with. Turn to the Woodturning Blueprint for some business advice to get you started in the right direction.