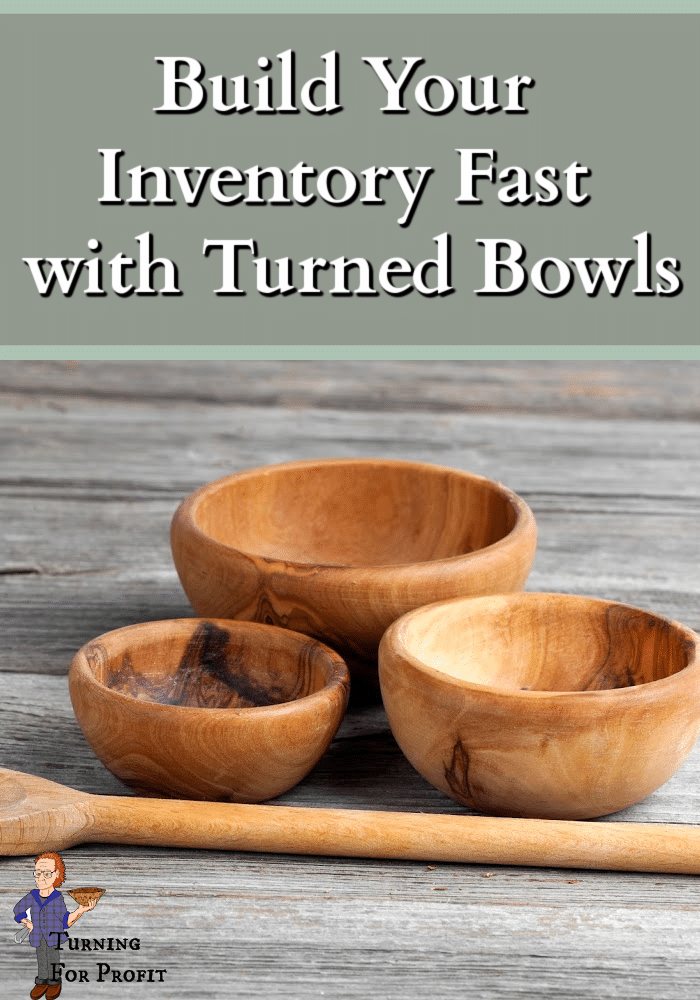

Every wood turner needs a collection of turned bowls in his inventory to prove his skills to the public. Bowls are easy sellers at craft fairs and galleries. They are useful, decorative, and can really showcase the creative skill of the turner. Bowls are also good practice pieces to warm-up at the lathe. At one fair I was at, a fellow-turner had a pile of quickly turned bowls for $25 each and sold out 1/2 way through the first day of the 2 day show.

Bowls can be quickly turned to build inventory before a show, or they can be exquisitely and uniquely finished to be a showcase piece that draws the praise of the crowd. Either way, turned bowls are an essential part of your merchandising.

After sharpening our tools, let’s look at a variety of turned bowls that could be in your inventory.

A selection of wooden turned bowls

Sharpening your turning tools

The easiest way to turn wood is with sharp tools. Before we look at the bowls here’s a video on sharpening turning tools.

I’m not perfect in my sharpening yet but even my imperfect bevels cut better when sharp.

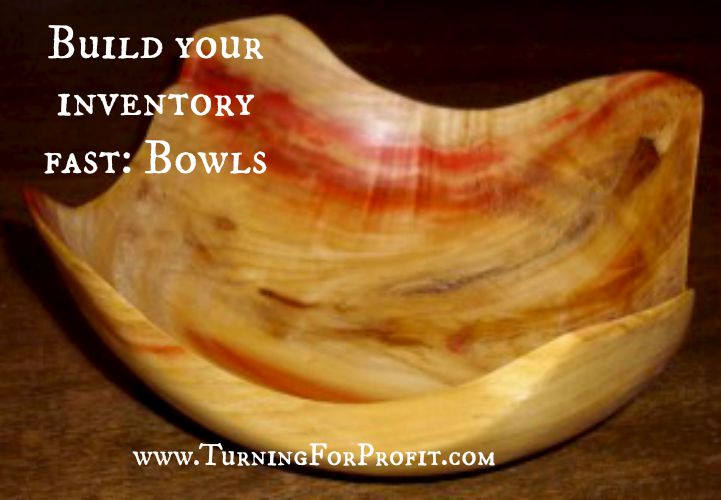

Natural Edged Turned Bowl

A bowl with a natural edge is challenging to turn since you don’t want to disturb the appearance of the edge of the bowl.

The end result can be quite stunning. This is actually turning a bowl in the opposite orientation for bowls with a turned edge.

Microwaved Dried Bowl

Take the wood from green to dried and finished bowl in one day!

It does take time to do the microwave treatment. Use defrost. No longer than two minutes. Wait until the bowl cools before you microwave it again. Depending on the wood, you might want to use an old microwave in the shop rather than the one in the kitchen.

Spalted Maple Bowl

When wood starts to decay it produces spalted wood. The bacteria in the wood create black lines that add character and interest to the turning.

If the wood is too far decayed then it will be punky and not hold together. Downed wood that is picked up in the forest will usually have some spalting. You’ll just have to try some and see what “turns” up!

Square Dish

This is a very contemporary bowl.

It was a challenge to turn but here’s how mine turned out.

It was a challenge to turn but here’s how mine turned out.

Truing A Dried Bowl

Usually turning bowls is a two step procedure. First you rough turn the bowl. Make the thickness of the bowl about 10% of its diameter, that is a 7″ bowl will be about 3/4″ thick. Then you set the bowl aside and turn it again when it is dry.

When you come back to the dried bowl it will have dried to a slightly oval shape on the tenon that you made when it was green. The tenon is used to attach the bowl onto the lathe and a round tenon will be more secure. This video gives you good instructions on how to true the tenon back to round so that you can continue turning your bowl.

Food Safe Wood Finishes

Since we are looking at bowls this week, this link gives information on food safe finishes for wooden items. I used coconut oil on the square turned bowl.

Each day I share a wood turning project on my facebook page.

What wood turning projects have you been working on? Leave me a comment.

I had hoped this site would have a bit more about how to set up your shop to increase production of bowls but it seems this site does not discuss production techniques but instead just talks about what to turn. I had hoped there would be more about efficient turning tips: ways of cutting bowl blanks, mounting options, coring, etc.

Is that somewhere here but I just can’t find the info?

Thank you for your comments Larry. The site is growing, all be it slowly, and bowl production is something I would like to try. If you enter production in the search bar you will get a couple of posts but they are focused on spindle turning and planning your production calendar.

Also, I turn green bowls to the final thickness, sand, and polish with beeswax, and then let them dry slowly in paper bags and have almost NEVER had a crack other than minor hairline cracks. I rarely see green turning to final polish anywhere on the web except for the double turning mentioned above (rough turn, let it dry for 6 months etc, then final turn and finish), which is sad because of the sometimes wonderful results of the slight to moderate warpage of the green wood.

Food safe wood finishes is a JOKE! Since 1978 ALL paint and paint related products MUST be edible after the VOC’s have dried. So if you can’t small the finish, in the USA, IT IS FOOD SAFE. Don’t pay extra for any product that claims to be food safe, they are ALL FOOD SAFE!