A wooden ball winder makes a great between centers turning project. Sometimes simple tools are the best and this tool is an easy turning project. Enjoy.

A variety of wood turning projects keeps the turner busy and free from boredom. To try out my new mini-lathe, a wooden ball winder or nostepinne is a good project. It is between centers turning and requires a good smooth finish on the working portion of the tool. A Wooden ball winder is called a nostepinne (as well as nostepinde and nystepinne). In my household it is just called a noste.

The working portion is where you wind the yarn creating a center pull ball. The ball winder has to be smooth so the yarn slides off easily. The handle can be as fancy or as plain as you wish. I match the handle to the size of the ball winder that I am turning. Yes you can have large winders to use for large skeins of yarn or small ones that work with smaller amounts of yarn.

Wood Turning Projects: Wooden Ball Winder

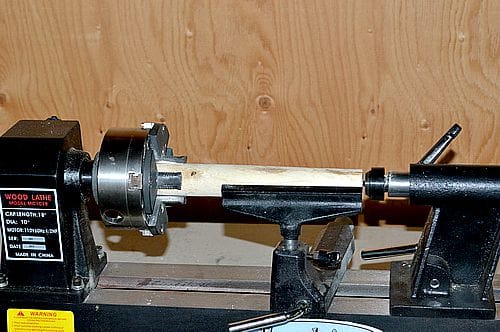

Step 1: Turn blank to round

Put your blank between centers in order to turn the piece round. You can do this with a drive spur and a live center or you can use your chuck to hold one end in place and a live center in the tail stock. By using a chuck you can turn the working end of the ball winder on the lathe (see Step 5). To turn the blank round you can use a roughing gouge, spindle gouge, or skew chisel depending on what you are turning.

Step 2: Mark out the Ball Winder

Decide how big the handle or grip needs to be and how long the working portion of the ball winder will be. This will affect the size of the balls of yarn you can wind. It is always a good idea to pencil in the rough dimensions of your wood turning projects so you can get an idea of the size and feel of the turning. You might want to keep a record of your different sizes on your shop notes.

Step 3: Shape and Smooth the Working End

I use a skew chisel for this portion of the turning. Working from the center to the end (left to right) smooth the surface and create a slight taper towards the end. Since this is the portion that you wind the ball of yarn on you want it smaller on the end to enable the yarn to slide off easily. You should define the junction with the skew chisel and round over the end as well.

Step 4: Shape the Handle and Finish the Body

The handle or grip for the nostepinne can be your original design. It just has to fit comfortably in your hand. Once you are satisfied with the handle then sand and finish your noste to your own taste. I sanded to 800 grit sandpaper and used carnuaba wax as the finish.

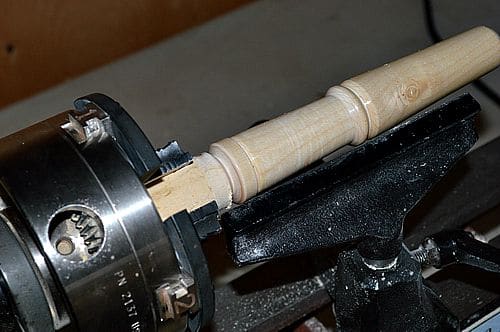

Step 5: Finish the End of the Ball Winder

By putting the blank in a key chuck I can remove the tail stock and finish the working end on the lathe. This allows you to get a great smooth finish on your ball winder. The picture shows me supporting the spinning wood as I gently smooth the end with a spindle gouge.

Step 6: Cut the Ball Winder off of the Lathe

Use your hand to support your wood and you use either a parting tool or your skew chisel to part the turning from the lathe. Take your time and do as much work on the lathe as you can. Then you won’t have as much hand finishing to do.

Step 7: Complete the Handle

Finish the end by removing the nub, sanding, and finishing the ball winder. I was able to end up with a very small nub by using a skew chisel and proceeding very slowly in parting the turning from the lathe.

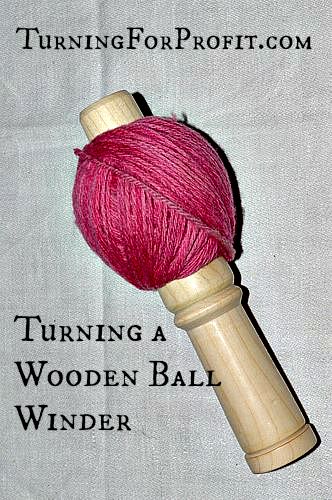

Step 8: Wrap a Ball of Yarn with Your Wooden Ball Winder

Attach the yarn to the spot between the handle and the working surface. Then wrap a few turn horizontally half way up the Ball Winder. Then start going over and under as you wrap the yarn around the Noste. Slowly turn the tool as you are wrapping. Here’s a picture part way through the process.

When you have used up all of your yarn untie the yarn from the middle. This is the part that you pull on to use the yarn. The yarn then comes from the center of the ball. This is called a “center pull ball” and it is great for knitters and other crafters because the ball won’t roll all over the place. Here’s your finished Wooden Ball Winder. Now you have a new item in your inventory of wood turning projects.

I hope you have enjoyed this Wood Turning Project. Everyone who knits or crochets could use one of these.

You can also turn other fiber arts tools. A yarn bowl keeps that yarn ball from rolling about the floor. A Niddy Noddy is used to make a skein of yarn from either bobbins (from spinning) or from a ball of yarn. Once you have a skein you can wash the yarn and dye it if you want to. One more great project is turning a needle case. You don’t need a large piece of wood for a needle case. I have made some from pen blanks.

Let me know, in the comments, if you tried this project and how it turned out!

What size do you turn the end to?

There is no specific size for a ball winder. You are looking for a winder that will fit comfortably in the hand of the user. Center pull balls work well with about an inch in diameter. You just want to taper the tool so the ball slides off easily.